U.S. Navy Shipbuilding Is Consistently Over Budget and Delayed Despite Billions Invested in Industry

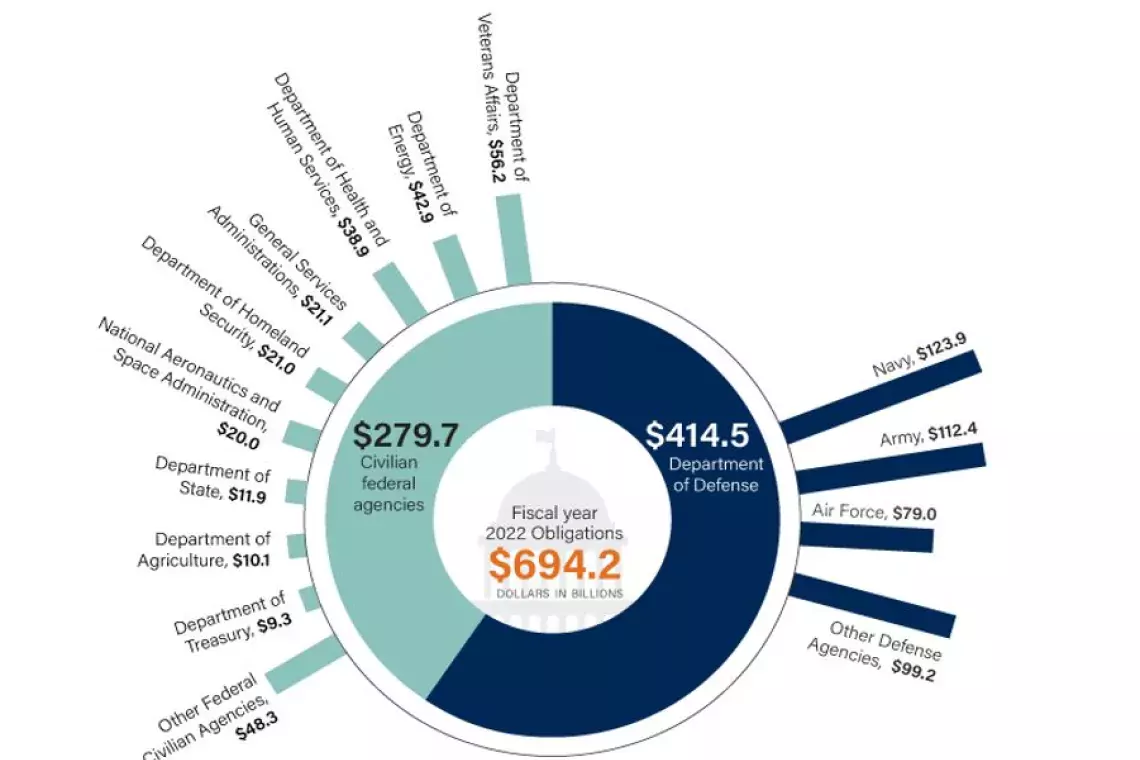

Despite nearly doubling its shipbuilding budget over the last 2 decades, the U.S. Navy hasn’t increased its number of ships. The Navy and Department of Defense work with private companies to build ships and have invested billions of dollars to support the shipbuilding industrial base. But even with this investment, the industry has not been able to meet the Navy’s goals—jeopardizing the Navy’s ability to protect the U.S. from growing maritime threats and competition.

Today’s WatchBlog post looks at our recent work about these investments and the challenges with shipbuilding. Watch the video below to see GAO’s Shelby Oakley’s opening statement on this issue from her March testimony before Congress.

Why are shipbuilders not keeping up with the Navy’s goals?

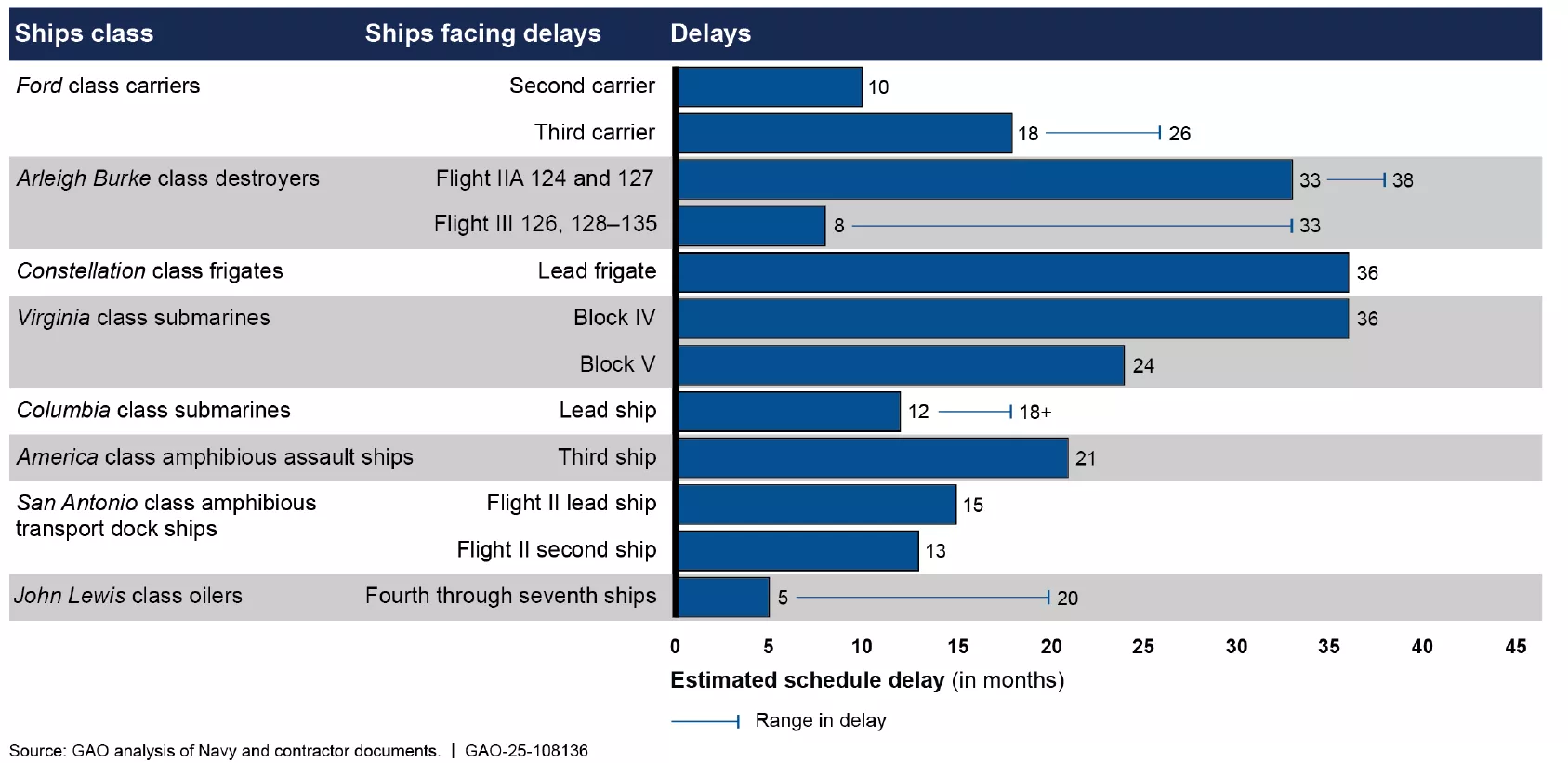

Private companies play a key role in building and repairing Navy ships. But for decades, these companies haven’t met the Navy’s goals for increasing the size of its fleet. This contributes to the Navy’s shipbuilding programs being consistently over budget and behind schedule. Estimated delays for some ships are as much as 3 years.

Navy Shipbuilding Delays in Months for Ships Under Construction, as of September 2024

Image

In our February report, we found that shipbuilders face two key challenges in meeting the Navy’s goals:

- First, some shipyards lack the physical space needed to complete the volume of work the Navy wants in the time it wants. Some shipyards also have aging infrastructure that can delay efforts.

- Second, shipbuilders don’t have enough workers to meet the Navy’s demands. These companies struggle to recruit and retain staff, especially those with the skills needed to do the work.

The Navy is aware of these challenges, but it consistently plans to build more ships for the fleet than the private shipbuilders have been able to achieve. The Navy isn’t considering shipbuilders’ capacity in its plans for growing and maintaining its fleet.

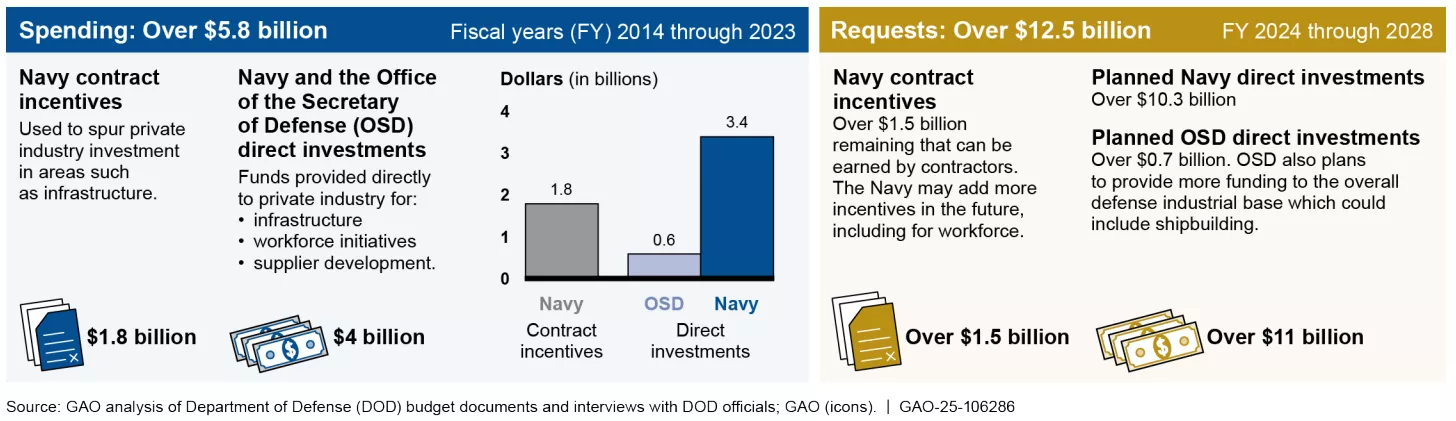

The Navy and the Department of Defense are taking steps to help private companies with shipbuilding. For example, they’ve invested billions to help increase shipbuilding capacity, such as helping with infrastructure improvements at shipyards and workforce development.

DOD Investments and Budget Requests for the Shipbuilding Industrial Base, FY 2014-2028

Image

But when we looked closer at these efforts, we found that the Navy hasn’t fully assessed whether its investments are working as intended, yet it continues to expect that the shipbuilders will achieve different results. Without this assessment, the Navy is poorly positioned to address shipbuilding challenges that are affecting its mission.

We also found that the Navy and DOD aren’t fully coordinating their investments to prevent potential duplication or overlap in efforts. A strategy and coordinated leadership around shipbuilding efforts could help ensure the Navy is getting what it needs from these investments.

Further, we made several recommendations to address these issues. The Navy recently stood up an office that is positioned to develop the type of strategy that would help address our recommendations.

Two examples illustrate the challenges seen at shipyards

Among the Navy’s efforts to expand its fleet are two new classes of nuclear-powered submarines that are drastically over budget and behind schedule. These submarines are critical to U.S. efforts to deter nuclear threats from our adversaries and respond to a wide range of potential maritime threats.

The Virginia class submarine (Block V) has been in production since 2019 and promises increased capabilities for 10 subs. The Navy set a goal of producing two submarines per year with the project completed by 2028. But in June 2024, we found that the program’s rate of production is at about 60% of its annual goal—putting it years behind schedule.

Much of this delay rests on the shipbuilder’s capacity to meet construction deadlines. The shipbuilder faces workforce shortages that have slowed progress. While the shipbuilder is working to outsource some of its work to other shipbuilders and build its workforce, delays are costing taxpayers money. About $530 million more is estimated to complete the first two submarines in this class.

The Columbia class submarine program is also delayed and could end up costing taxpayers hundreds of millions of dollars in additional construction costs for the first submarine alone.

The Navy initially planned to spend $130 billion to acquire 12 of these nuclear-powered ballistic missile submarines. The first submarine is planned to be available for operations in 2030. In our September 2024 report, we reported that construction consistently fell short of targets and that the submarine would be delayed by at least a year. Delays and cost increases both stem from workforce and capacity challenges among shipbuilders and the companies that supply them with materials. Without action on these issues, it is likely the price tag for these submarines will continue to grow along with delays that slow its completion.

Learn more about the Navy’s challenges in meeting its shipbuilding and repair needs by checking out our most recent report.

- GAO’s fact-based, nonpartisan information helps Congress and federal agencies improve government. The WatchBlog lets us contextualize GAO’s work a little more for the public. Check out more of our posts at GAO.gov/blog.

- Got a comment, question? Email us at blog@gao.gov.