Science and Tech Spotlight: Alternative Materials for Solar Cells

Fast Facts

This Spotlight examines evolving solar cell technology. Most electricity-generating solar cells are made with crystalline silicon in a process that is complex, expensive, and energy-intensive. Alternative materials may perform better and be easier and cheaper to make. Some absorb light 10-100 times more efficiently using thin films. In addition, these cells can be manufactured quickly and easily, reducing cost.

Some alternative materials remain in the early stages of research and development but others are already in use. For example, cadmium telluride solar cells are produced commercially and cost about the same as crystalline silicon cells.

Highlights

Why This Matters

US generation of electricity from solar energy could grow six-fold by 2050. Alternatives to commonly used crystalline silicon cells may reduce material usage, manufacturing capital expenditures, and lifecycle greenhouse gas emissions. Many of these new materials, however, are under development, and more research is needed to better understand their potential.

The Technology

What is it? Most solar cells (the components that generate electricity from sunlight) are currently produced with crystalline silicon in a process that is complex, expensive, and energy-intensive. Alternative materials—such as cadmium telluride, amorphous silicon, perovskites, and organic (carbon-containing) compounds—applied in thin layers of film may perform better and be easier and cheaper to manufacture.

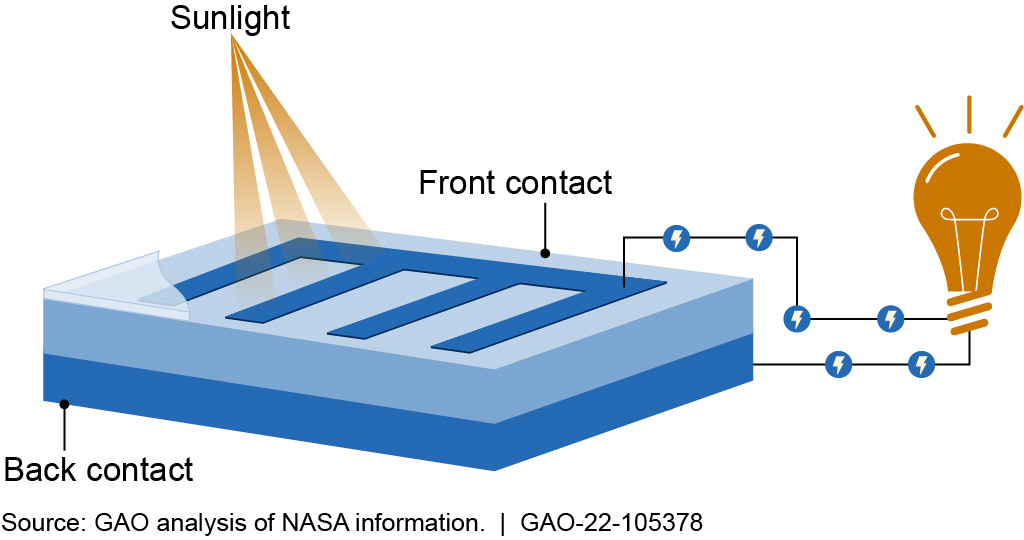

How does it work? As sunlight shines on a solar cell, some of the energy is absorbed to generate electricity either for immediate use or for storage in batteries (see fig. 1). The more readily a given solar cell absorbs light and transforms it into electricity, the higher its efficiency. The electric current generated by sunlight flows through wires that connect the front and back contacts of the solar cell.

Figure 1. A simplified representation of how a solar cell generates an electric current.

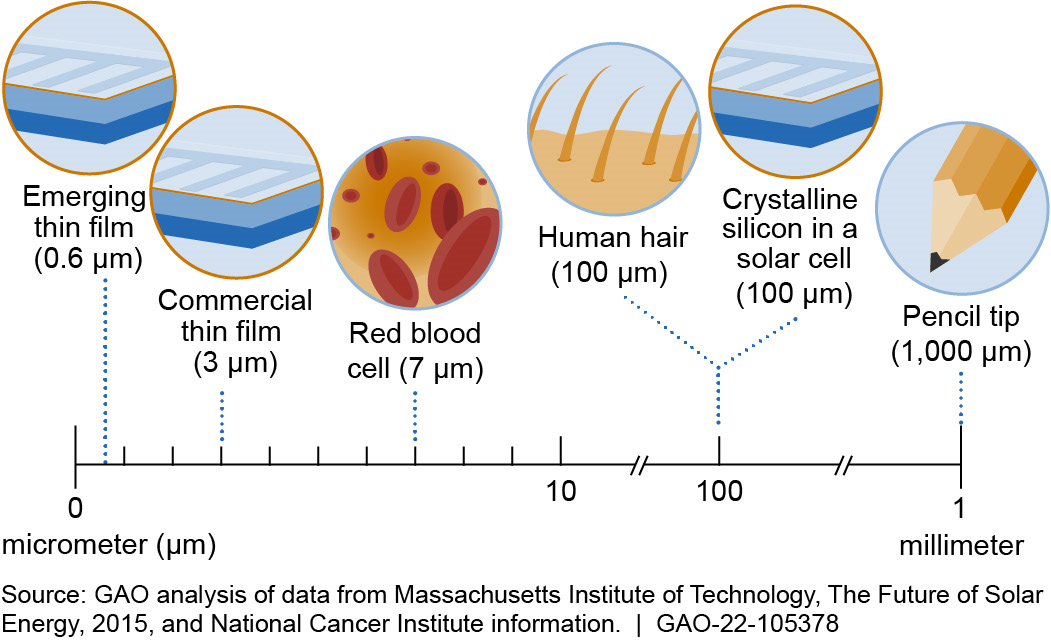

Some alternative materials absorb light 10 to 100 times more strongly than crystalline silicon, allowing them to produce electricity using less material. In turn, solar cells made with these materials are typically thinner and weigh less. In addition, these thin film solar cells can be manufactured quickly, reducing cost.

How mature is it? The maturity of these alternative materials varies widely, with some currently used to manufacture solar cells and others in the early stages of research and development. For example, cadmium telluride cells and copper indium gallium diselinide cells together account for roughly 10 percent of current solar cells and they are already cost-competitive with crystalline silicon cells.

Novel solar cells under development use a variety of materials. Among them is amorphous silicon, which is non-crystalline and can be deposited as a thin film. Perovskites are an emerging class of materials with rapidly increasing efficiencies. Organic materials offer yet another option for thin films. They consist of carbon-containing compounds, either long chains or molecules, tailored to absorb specific wavelengths of light. Researchers are also investigating the use of quantum dots—microscopic particles of compounds such as cadmium telluride, cadmium selenide, indium phosphide, or zinc selenide, that are able to produce electricity from light.

Although these diverse materials differ in their chemical composition, they all fall under the category known as thin films because of the extremely thin layer—comparable in thickness to a red blood cell—in which they are applied (see fig. 2). In addition to being easy to produce and relatively inexpensive, these materials can be deposited on a variety of substrates, including flexible plastics in some cases.

Figure 2. Current and potential alternative materials for solar cells are applied in extremely thin layers, with emerging materials being the thinnest.

In addition to absorbing light, solar cells must convert it to electricity. While promising, commercial thin film solar cells currently average a conversion efficiency in the range of 12 to 15 percent, compared to 15 to 21 percent for crystalline silicon, according to a Massachusetts Institute of Technology (MIT) study. In addition, they require appropriate sealing materials to protect them from ambient oxygen and moisture. As a result, many alternative solar cell materials are currently under development or limited to specialized applications.

Opportunities

- Reduced land use. Large solar farms can reduce usable farmland and affect previously undisturbed habitats. These new materials could reduce the amount of land needed for solar arrays by increasing efficiency and offering the flexibility to add more solar capacity to existing infrastructure by, for example, embedding solar cells in transparent replacement windows or in the body panels of electric cars.

- Lower greenhouse gas emissions. Electricity generation using solar cells reduces greenhouse gas emissions compared to fossil-fuel combustion. In addition, the use of alternative solar cell materials may release fewer greenhouse gases across their life cycles compared to crystalline silicon.

- Reduced transmission and distribution-based energy loss. The U.S. Energy Information Administration estimates that about 5 percent of the electricity transmitted and distributed is lost, partially because electricity production often occurs far from customer sites. Novel solar cells based on alternative materials and deployed close to the customer could reduce the need to transmit and distribute electricity over long distances, thereby reducing loss.

- Improved resilience. Producing and storing electricity locally may help communities better prepare for power outages and restore power more quickly during and after natural disasters or other unforeseen events by designing electricity generating systems to operate even when disconnected from distant electricity producers.

- Lower manufacturing cost. Production of solar cells using alternative materials relies on fewer and easier steps than the production of crystalline silicon devices. This could decrease manufacturing costs, depending on the material used.

Challenges

- Unknown installation cost. Solar cells are just one element of the overall cost of solar generation. In 2014, solar cells accounted for one third of the total installation cost for utility-scale systems and one fifth of the total installation cost for residential systems, according to an MIT study. However, costs for emerging materials are not known at this time.

- Material scarcity. Some alternative materials for solar cells use scarce or critical materials. For example, tellurium is typically a byproduct of copper refining, which limits its market availability. Tellurium’s low concentration in the earth’s crust precludes mining it as a primary product at today’s price.

- Toxicity. Existing solar cells and those under development may contain toxic materials that can be harmful when ingested or absorbed.

- End of life disposal. The current regulatory scheme for managing the end of life of solar cell modules is complex and varies by jurisdiction.

Policy Context and Questions

As alternative materials for solar cells continue to evolve and mature, some key questions that policymakers could consider include:

- What steps could help encourage further development and use of alternative energy sources such as solar cell materials?

- What analyses of incentives and barriers can determine whether government stimulus may be needed for private sector investment in solar cell materials and what are the trade-offs of such a stimulus?

- What actions could help ensure sufficient understanding of the human health and environmental impacts of various solar cell materials across the full lifecycle?

For more information, contact Karen Howard at 202-512-6888 or HowardK@gao.gov.