Navy Shipbuilding: Increasing Supervisors of Shipbuilding Responsibility Could Help Improve Program Outcomes

Fast Facts

The Navy often accepts delivery of incomplete ships after significant delays in construction and considerable cost growth.

At major shipyards, the Navy has an onsite organization—the Supervisors of Shipbuilding, Conversion, and Repair—that's responsible for overseeing construction and managing shipbuilding contracts. The Supervisors' expertise provides foresight into shipbuilding problems, but we found the Navy isn't taking full advantage of it.

Among other things, we recommended ensuring that the Supervisors are consistently represented earlier in the shipbuilding process, starting before contracts are awarded.

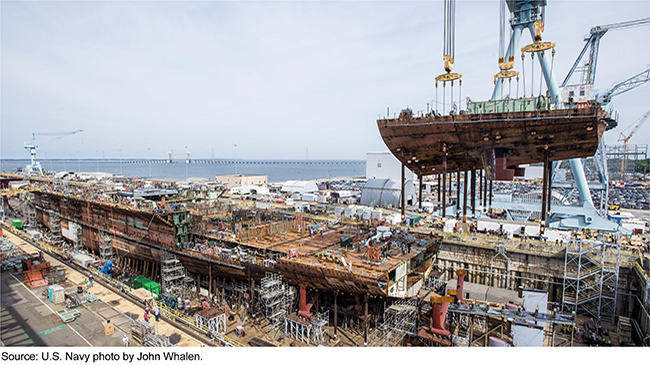

A crane moves the lower stern into place on an aircraft carrier.

Highlights

What GAO Found

Over the past decade, GAO found that the U.S. Navy has faced significant challenges in meeting its shipbuilding goals, experiencing years of construction delays, billions of dollars in cost growth, and frequent quality and performance shortfalls. The Supervisors of Shipbuilding, Conversion and Repair (SUPSHIP) serve as the Navy's on-site technical, contractual, and business authority for the construction of Navy vessels at major private shipyards. The SUPSHIPs are responsible for evaluating the construction and business practices of Navy shipbuilders, but face challenges in improving shipbuilding results (see figure).

Factors Limiting the Ability of the Navy's Supervisors of Shipbuilding, Conversion and Repair (SUPSHIP) to Help Improve Shipbuilding Program Results

These challenges impede the SUPSHIPs' effectiveness and accountability in a number of ways:

- Variation in quality requirements across Navy shipbuilding contracts hinders the SUPSHIPs' ability to provide consistent oversight of shipbuilding quality.

- Limited input from the SUPSHIPs prior to contract awards does not leverage their expertise to support well-informed decision-making.

- Omission of SUPSHIP reporting from the Navy's process for approving acceptance of ships from the shipbuilders reduces accountability and misses opportunities to ensure that independent SUPSHIP input on ship quality and readiness informs this key decision.

- The SUPSHIPs' position within the Naval Sea Systems Command and their accountability to different technical and acquisition organizations dilutes their ability to be a distinct, authoritative voice in decision-making for Navy shipbuilding programs. Congress passed legislation in December 2021 to establish a Deputy Commander dedicated to the SUPSHIPs, which should help improve their authority and accountability.

Why GAO Did This Study

Despite the efforts of the SUPSHIPs and others to assure construction quality and contract execution, Navy shipbuilding results have regularly fallen short of program expectations. These results have raised questions about the Navy's ability to effectively oversee shipbuilder performance throughout the construction of new ships.

Congress included a provision in a Senate report for GAO to review the SUPSHIPs' oversight efforts. GAO examined, among other objectives, the SUPSHIPs' role in assuring shipbuilding quality and any challenges that limit their ability to help improve shipbuilding program results.

To do this work, GAO reviewed federal regulations as well as policy, guidance, and reporting related to the SUPSHIPs' oversight activities and results. GAO also interviewed DOD and Navy officials about shipbuilding oversight and the SUPSHIPs' role in the execution of shipbuilding programs.

Recommendations

GAO is making five recommendations to the Navy, including that it take steps to ensure regular use of its quality program standard in shipbuilding contracts; provide the SUPSHIPs with direct representation in evaluation and decision-making processes prior to contract awards; and require the SUPSHIPs to report on the quality and readiness of each ship prior to the Chief of Naval Operations' approval decisions for ship acceptance. The Navy agreed with all five recommendations.

Recommendations for Executive Action

| Agency Affected | Recommendation | Status |

|---|---|---|

| Department of the Navy | The Secretary of the Navy should determine if the Naval Sea Systems Command's Quality Program Standard for Construction of Naval Vessels requires any updates and then take steps to ensure regular use of the standard in Navy shipbuilding contracts. (Recommendation 1) |

The Department of the Navy concurred with this recommendation but, as of July 2025, has yet to demonstrate actions to implement it. In July 2025, the Navy stated it is working on an update to the Quality Program Standard for Construction of Naval Vessels, with anticipated completion in the second quarter of fiscal year 2026. We will continue to monitor the Navy's actions in response to this recommendation to ensure that consistent quality requirements are included in shipbuilding contracts to support effective shipbuilding surveillance.

|

| Department of the Navy | The Secretary of the Navy should evaluate whether opportunities exist for additional targeted oversight by the SUPSHIPs of critical government-furnished equipment away from the shipyards to support improvements to overall shipbuilding results. (Recommendation 2) |

The Department of the Navy concurred with this recommendation but, as of July 2025, has yet to demonstrate actions to implement it. In July 2025, the Navy shared that it is working to implement actions resulting from a working group previously developed to evaluate the need for additional oversight. The estimated completion date for this action is the first quarter of fiscal year 2026. We will continue to monitor the Navy's actions in response to this recommendation to support efficient and effective shipbuilding oversight.

|

| Department of the Navy | The Secretary of the Navy should ensure that, prior to contract award decisions, the Naval Sea Systems Command evaluates the extent to which awarding a shipbuilding contract to a prime contractor that is not the shipbuilder presents additional government risk related to contractor business systems compliance and determine options, as needed, to mitigate the risk. (Recommendation 3) |

The Department of the Navy concurred with this recommendation but, as of July 2025, has yet to demonstrate actions to implement it. In July 2025, the Navy stated that it is conducting a pilot program with PEO Ships to assess the value of incorporating lessons learned and government risk assessments into pre-award decision making. According to the Navy it will develop a formalized process for evaluating and mitigating contract business system compliance risk based on the pilot program. The Navy stated it anticipates finalizing updates to NAVSEA Instruction 5000.2 with these changes by the end of fiscal year 2025. We will continue to monitor the Navy's actions in response to this recommendation to ensure that the Navy sufficiently accounts for any applicable risk to the government from a prime contractor not being the shipbuilder for a shipbuilding program.

|

| Department of the Navy | The Secretary of the Navy should ensure that Naval Sea Systems Command Instruction 5450.36C, Mission, Functions, and Tasks of the Supervisors of Shipbuilding, Conversion and Repair, United States Navy, is updated to provide the SUPSHIPs direct representation in the evaluation and decision-making processes for all shipbuilding programs, beginning with the pre-contract award stages of requirements development and ship design. (Recommendation 4) |

The Department of the Navy concurred with this recommendation but, as of July 2025, has yet to demonstrate actions to implement it. In July 2025, the Navy stated it had updated Naval Sea Systems Command Instruction 5450.56D to address this recommendation and document requirements from the 2022 NDAA for additional SUPSHIP oversight. However, the Navy has yet to provide us with the updated instruction to demonstrate that its changes address this recommendation. We will continue to monitor the Navy's actions in response to this recommendation to ensure direct SUPSHIP representation in decision-making processes for shipbuilding programs.

|

| Department of the Navy | The Secretary of the Navy should require that, in coordination with the Commander of Naval Sea Systems Command, the SUPSHIPs' Deputy Commander provide a report to the Chief of Naval Operations that attests to the quality and readiness of each ship prior to the approval of ship acceptance. (Recommendation 5) |

The Department of the Navy concurred with the intent of this recommendation, but, as of July 2025, has yet to demonstrate actions to implement it. In July 2025, the Navy stated that work is ongoing to update its instruction related to ship delivery and anticipates completion in the first quarter of fiscal year 2026. We will continue to monitor the Navy's actions in response to this recommendation to ensure that the SUPSHIPs inform Navy decisions to accept delivery of new ships

|