Navy Maintenance: Persistent and Substantial Ship and Submarine Maintenance Delays Hinder Efforts to Rebuild Readiness

Fast Facts

The Navy continues to face persistent and substantial maintenance delays that hinder its ability to stay ready for operations and training. Since fiscal year 2014, Navy ships have spent over 33,700 more days in maintenance than expected. Insufficient shipyard capacity and a shortage of skilled workers are among the contributing factors we identified.

The Navy has efforts underway to improve its maintenance operations. They will require years to implement, sustained management attention, and greater funding.

In the reports upon which this testimony is based, we made 17 recommendations. Only 6 have been fully carried out.

USS Albany Undergoing Extended Maintenance at Norfolk Naval Shipyard

Dry dock

Highlights

What GAO Found

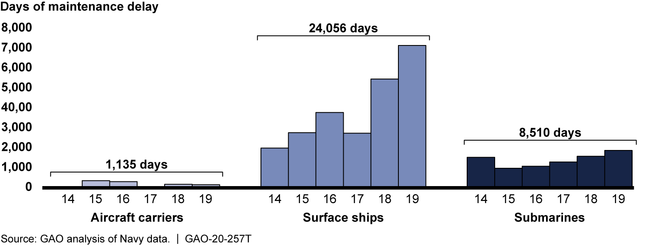

The Navy continues to face persistent and substantial maintenance delays that affect the majority of its maintenance efforts and hinder its attempts to restore readiness. From fiscal year 2014 to the end of fiscal year 2019, Navy ships have spent over 33,700 more days in maintenance than expected. The Navy was unable to complete scheduled ship maintenance on time for about 75 percent of the maintenance periods conducted during fiscal years 2014 through 2019, with more than half of the delays in fiscal year 2019 exceeding 90 days. When maintenance is not completed on time, fewer ships are available for training or operations, which can hinder readiness.

Navy's Days of Maintenance Delay, Fiscal Years 2014 through 2019

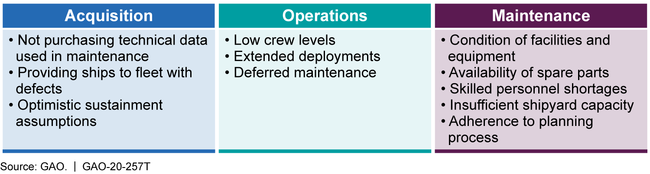

GAO identified multiple factors that contribute to maintenance delays, including insufficient shipyard capacity, shortage of skilled personnel, and deferred maintenance during operational deployments, among others. Ships awaiting or delayed in maintenance incur operating and support costs. For example, GAO estimated that the Navy spent more than $1.5 billion in support costs from fiscal years 2008 through 2018 due to delayed maintenance for attack submarines.

Factors Contributing to Navy Maintenance Delays

The Navy has several efforts underway to improve its maintenance operations, but they will take years to implement, and will require sustained management attention and funding above current levels. For example, the Navy estimates it will take 20 years to improve the infrastructure at its shipyards, 4 years to restore ship crew levels, and several years to improve maintenance planning. Until the Navy addresses these challenges, it will be hindered in its ability to rebuild readiness and prepare for the future, particularly as it grows the size of the fleet.

Why GAO Did This Study

The 2018 National Defense Strategy emphasizes that restoring and retaining readiness is critical to success in the emerging security environment. The Navy is working to rebuild its readiness while also growing and modernizing its aging fleet of ships. A critical component of rebuilding Navy readiness is implementing sustainable operational schedules, which hinge on completing maintenance on time. We have reported that the Navy faces persistent challenges with completing required maintenance on time.

This statement provides information on (1) the magnitude of maintenance delays for Navy ships and submarines, (2) factors contributing to maintenance delays, and (3) the Navy's efforts to address these factors. GAO also discusses its prior recommendations on the factors contributing to Navy maintenance delays and the Navy's progress in addressing the recommendations.

This statement is based on previously published work from 2015 through 2019 on Navy maintenance, ship acquisition, crew size, ship maintenance and deployment schedules, the condition of Naval shipyards, and recruiting skilled maintenance personnel.

Recommendations

GAO made 17 recommendations in prior work cited in this statement. The Department of Defense generally concurred with most of GAO's recommendations, and has fully implemented 6. Continued attention is needed to ensure that the remainder of these recommendations are addressed.