Military Depots: Actions Needed to Improve Poor Conditions of Facilities and Equipment That Affect Maintenance Timeliness and Efficiency

Fast Facts

Military Depots: Services Need to Take Actions to Improve Poor Condition of Facilities and Equipment That Affect Maintenance Timeliness and Efficiency

DOD operates 21 depots that maintain, overhaul, and repair complex weapons systems and equipment.

We found

The facility conditions were poor at most depots

Depot equipment was generally older than its expected service life

Declining performance over the last 10 years at most depots reduced the availability of weapons systems for training and operations

The military services can't determine how much of the decline is due to facility and equipment problems

While the services have started planning to improve depots as required, we recommended they track maintenance delays and incorporate key goals and performance metrics into their plans.

This depot drydock allows maintainers to work on the hull of a submarine.

Submarine in drydock

Highlights

What GAO Found

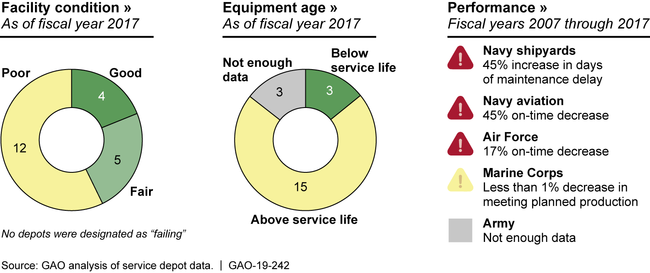

The condition of facilities at a majority of the Department of Defense's (DOD) depots is poor and the age of equipment is generally past its useful life, but the services do not consistently track the effect that these conditions have on depot performance. Twelve of the 21 depots GAO reviewed––more than half––had “poor” average facility condition ratings (see figure). Some facilities also serve functions for which they were not designed, reducing their efficiency. In addition, the average age of depot equipment exceeded its expected useful life at 15 of the 21 depots. These factors contributed, in part, to a decline in performance over the same period. From 2007 to 2017, performance at the depots generally declined, reducing the availability of the weapon systems repaired for training and operations. Optimizing facilities and equipment at the depots can improve their maintenance efficiency. For example, the Navy estimates that its shipyard optimization effort will save over 325,000 labor days per year, which would allow an additional submarine overhaul annually. However, the services lack data on the effect that facilities and equipment conditions have on maintenance delays, hindering DOD's ability to effectively target investments to the highest priorities.

Summary of Facilities, Equipment, and Performance at 21 Service Depots

DOD and the services' approach for managing investments to improve the efficiency and effectiveness of its depots lacks elements important to addressing key challenges. The services have efforts underway to complete their plans by February 2019 to address their depots' facility and equipment needs. However, GAO found that these plans are preliminary and will not include key elements, such as analytically-based goals; results-oriented metrics; a full accounting of the resources, risks, and stakeholders; and a process for reporting on progress. Addressing the poor conditions at DOD's 21 depots will cost billions and require sustained management attention over many years. However, the DOD office responsible for depot policy does not monitor or regularly report on depot improvement efforts to DOD decision makers and Congress. Until DOD and the services incorporate these key elements into the management approach for their depot investments, they risk continued deterioration of the depots, hindering their ability to meet the Secretary of Defense's goals for improving readiness and reducing operating and support costs.

Why GAO Did This Study

The military services' 21 depots maintain the readiness of critical weapon systems such as ships, aircraft, and tanks needed for military operations. The condition of depot facilities and equipment directly affects the timeliness of maintenance and the readiness of the weapon systems they repair. The services have invested over $13 billion in the depots from fiscal year 2007 to fiscal year 2017.

Senate Report 115-125 included a provision for GAO to examine the services' investment in and performance of their depots. GAO evaluated (1) the condition of depot facilities and equipment, their relationship to depot performance, and the services' tracking of the relationship to depot performance and (2) the extent to which DOD and the services have developed an approach for guiding depot investments to address key challenges. GAO also provides an overview summary for each depot. GAO reviewed data from fiscal years 2007 through 2017 on depot investment, performance, and the age and condition of facilities and equipment; reviewed agency guidance; and interviewed DOD, service, and depot officials.

Recommendations

GAO is making 13 recommendations to improve data collection on the effect of facilities and equipment condition on depot performance, and develop plans that incorporate key elements to guide depot investments. DOD concurred with 12 recommendations, but did not agree to monitor and report on depot investments. We continue to believe monitoring and reporting will enhance DOD's efforts to improve its depots.

Recommendations for Executive Action

| Agency Affected | Recommendation | Status |

|---|---|---|

| Department of Defense | The Secretary of the Army should ensure that Army Materiel Command establishes measures for its depots to track facility or equipment conditions that lead to maintenance delays. (Recommendation 1) |

DOD concurred with this recommendation. As of May 2023, Army officials have stated that they plan to develop a new metric - Work Center Downtime; this metric will measure and record unplanned equipment downtime as an indicator of impact to production. For facilities, the Army is transitioning to a new data system - BUILDER - which is intended to provide better insight into facility condition. However, it is not clear to what extent the Army intends to track situations where facility problems lead to maintenance delays. The Army anticipates completing this recommendation by the end of fiscal year 2023. As of July 2025, DOD has not provided additional information related to this recommendation.

|

| Department of Defense | The Secretary of the Army should ensure that Army Materiel Command implements tracking of the measures for identifying when facility or equipment conditions lead to maintenance delays at each Army depot. (Recommendation 2) |

DOD concurred with this recommendation. As of May 2023, the Army intends to begin tracking equipment problems that lead to maintenance delays by the end of fiscal year 2023. The Army will complete transitioning to a new facility data system in July 2022; however, it is not clear if they will be tracking delays caused by facility problems. As of July 2025, DOD has not provided additional information related to this recommendation.

|

| Department of Defense | The Secretary of the Navy should ensure that Naval Sea Systems Command and the Commander, Fleet Readiness Centers establish measures for their depots to track facility or equipment conditions that lead to maintenance delays. (Recommendation 3) |

DOD concurred with this recommendation. In July 2019, the Navy changed its delay code for maintenance delays. Prior to that, the Navy had a single delay code for all facility, equipment, and tooling-caused delays. After July 2019, the Navy created 3 separate codes - one each for facility, equipment, and tooling-caused maintenance delays, which it could then use to better analyze the effects of these on maintenance throughput. This change allows the Navy to track the causes of maintenance delays and meets the intent of this recommendation.

|

| Department of Defense | The Secretary of the Navy should ensure that Naval Sea Systems Command and the Commander, Fleet Readiness Centers implement tracking of the measures for identifying when facility or equipment conditions lead to maintenance delays at each Navy depot. (Recommendation 4) |

DOD concurred with this recommendation. According to Navy officials, they began generating reports using the new facility, equipment, and tooling delays codes in August 2019. Examples of these reports were provided to GAO. They then used these reports to analyze to most common causes of delays and adjusted equipment maintenance and investment plans, as appropriate. These actions meet the intent of this recommendation.

|

| Department of Defense | The Secretary of the Air Force should ensure that Air Force Materiel Command establishes measures for its depots to track facility or equipment conditions that lead to maintenance delays. (Recommendation 5) |

DOD concurred with this recommendation. According to Air Force officials, the Facility Status Tracker (FaST) was designed & built to track infrastructure/equipment insufficiencies leading to disruptions. The tool is designed to capture disruptions to industrial plant equipment and facility capabilities as well as assign an estimated dollar value to each disruption. The tracker has been delayed over the last year due to research of optional programs and ensuring the security of the data. The far term goal is to house the tracker within the IBM MAXIMO program. In March 2021, the Tracker was launched utilizing an interim data collection tool until the MAXIMO pilot is tested/developed. This tool meets the intent of this recommendation.

|

| Department of Defense | The Secretary of the Air Force should ensure that Air Force Materiel Command implements tracking of the measures for identifying when facility or equipment conditions lead to maintenance delays at each Air Force depot. (Recommendation 6) |

DOD concurred with this recommendation. In 2021, the Air Force developed a process for identifying and tracking when facility and equipment problems led to facility delays. Specifically, the Air Force is using an existing information system to track these delays and assign estimated dollar values to the disruptions. It can then use this data to help inform investment decisions. In addition, the Air Force in April 2022 tasked an organization within the Air Force Sustainment Center with responsibility for this tracking and analysis, writing this responsibility into the Depot Maintenance Management manual. We believe these actions meet the intent of this recommendation.

|

| Department of Defense | The Commandant of the Marine Corps should ensure that Marine Corps Logistics Command establishes measures for its depots to track facility or equipment conditions that lead to maintenance delays. (Recommendation 7) |

DOD concurred with this recommendation. In September 2022, the Marine Corps incorporated this ability into their Master Scheduling Support Tool (MSST). The Marine Corps provided documentation that the MSST system now includes codes that can identify when a facility or equipment condition led to a maintenance delay. This consists of specific delay codes that can be entered by maintainers to indicate when equipment or facility issues caused the delay. Implementing this change addresses the recommendation.

|

| Department of Defense | The Commandant of the Marine Corps should ensure that Marine Corps Logistics Command implements tracking of the measures for identifying when facility or equipment conditions lead to maintenance delays at each Marine Corp depot. (Recommendation 8) |

DOD concurred with this recommendation. In September 2022, the Marine Corps incorporated this ability into their Master Scheduling Support Tool (MSST). The Marine Corps provided documentation that the MSST system now includes codes that can identify when a facility or equipment condition led to a maintenance delay. This consists of specific delay codes that can be entered by maintainers to indicate when equipment or facility issues caused the delay. To track these delays, Marine Corps officials have the system produce a report detailing the use of the various delay codes over a given period of time. This allows them to see when a delay was produced by a facility or equipment problem and any associated delay costs. Implementing this change addresses the recommendation.

|

| Department of Defense | The Secretary of the Army should ensure that Army Materiel Command incorporates in its depot optimization plan, key results-oriented elements including analytically-based goals, results-oriented metrics, identification of required resources, risks, and stakeholders, and regular reporting to decision makers on progress. (Recommendation 9) |

DOD concurred with this recommendation. The Army issued its "Master Plan for the Army's Organic Industrial Base Infrastructure" in July 2019. However, the Army issued a new Modernization Strategy shortly thereafter, which meant that the master plan was not aligned with the Army's future force structure. The Army released a revision to the Infrastructure Plan that incorporates the Army's modernization strategy and the depots' needs into an overall Army Depot Modernization Strategy in 2022. In July 2022, we reviewed the revised plan to assess the extent to which it includes the results-oriented elements we recommended. The plan includes most of the results-oriented elements, but remains incomplete. Specifically, the plan does not include a performance management framework that specifies how progress on the plan will be reviewed by leadership. Without this, it is not clear how any necessary adjustments to the plan will be made. As of May 2023, the Army anticipates completing this recommendation by the end of fiscal year 2023. As of July 2025, DOD has not provided additional information related to this recommendation.

|

| Department of Defense | The Secretary of the Navy should ensure that Commander, Fleet Readiness Centers incorporates in its depot optimization plan, key results-oriented elements including analytically-based goals, results-oriented metrics, identification of required resources, risks, and stakeholders, and regular reporting to decision makers on progress. (Recommendation 10) |

DOD concurred with this recommendation. The Commander, Fleet Readiness Centers (COMFRC) issued an "Infrastructure Optimization Plan Assessment for Depot-Level FRCs" in Jan. 2018 and also provided an update to OSD in 2020. In July 2022, we reviewed the revised plan to assess the extent to which it includes the results-oriented elements we recommended. The plan includes most of the results-oriented elements, but remains incomplete. Specifically, the plan does not include a performance management framework that specifies how progress on the plan will be reviewed by leadership, or a review of external factors that could affect implementation. As of May 2023, the Navy has said it will complete this recommendation by the end of fiscal year 2024. As of July 2025, DOD has not provided additional information related to this recommendation.

|

| Department of Defense | The Secretary of the Air Force should ensure that Air Force Materiel Command incorporates in its depot optimization plan, key results-oriented elements including analytically-based goals, results-oriented metrics, identification of required resources, risks, and stakeholders, and regular reporting to decision makers on progress. (Recommendation 11) |

DOD concurred with this recommendation. The Air Force released its "Master Plan for Organic Industrial Base Infrastructure" in February 2019. It then provided an update - named "2.0" to OSD in response to Congressional interest in 2020. In February 2025, the Air Force completed its plan. Upon review, we assessed this plan to include the requisite results-oriented elements, including analytically based goals; results-oriented metrics; identification of resources needed, stakeholders involved, and risks to the project; as well as setting up a regular reporting mechanism to decision-makers. Those actions meet the intent of this recommendation.

|

| Department of Defense | The Commandant of the Marine Corps should ensure that Marine Corps Logistics Command incorporates in its depot optimization plan, key results-oriented elements including analytically-based goals, results-oriented metrics, identification of required resources, risks, and stakeholders, and regular reporting to decision makers on progress. (Recommendation 12) |

DOD concurred with this recommendation. The Marine Corps released a report on its Industrial Base in July 2019 and as of May 2021, the Marine Corps had implemented a Depot of the 21st Century initiative in order to establish the framework for modernization that will support the Marine Corps' future force. In July 2022, we reviewed the Marine Corps plan to assess the extent to which it includes the results-oriented elements we recommended. The plan includes most of the results-oriented elements, but remains incomplete. Specifically, the plan does not include a performance management framework that specifies how progress on the plan will be reviewed by leadership, or include a review of external factors that could affect implementation. In May 2025, the Marine Corps submitted a revised depot plan to Congress. This report did include all the recommended elements, including goals, metrics, resources, and risks. This meets the intent of the recommendation.

|

| Department of Defense | The Secretary of Defense should ensure that the Assistant Secretary of Defense for Sustainment develops an approach for managing service depot investments that includes management monitoring and regular reporting to decision makers and Congress on progress. (Recommendation 13) |

DOD did not concur with our recommendation that the Assistant Secretary of Defense for Sustainment (ASD for Sustainment) develop an approach for managing service depot investments. In its response, DOD stated it could not develop such an approach until the services finalized and resourced depot optimization plans. DOD stated it would continue to monitor capital investments at service depots through the budget process. We continue to believe that the ASD for Sustainment should develop an approach for managing service depot investments that includes management monitoring and regular reporting to decision makers and Congress on progress for several reasons. First, our recommendation is focused on the ASD for Sustainment developing an approach for overseeing the services' overall depot investments, not just those contained in their optimization plans. Second, the ASD for Sustainment's early involvement in the services' development and resourcing of depot optimization plans could enhance service efforts to identify appropriate analytically-based goals aligned with the Secretary of Defense's readiness objectives, enhance optimization across the DOD enterprise, and ensure sustained senior leadership attention to achieving optimal depot efficiency and effectiveness. Third, while monitoring investments at the service depots through the budget process is an important aspect of oversight, the ASD for Sustainment could enhance the oversight of and accountability over depot investments through a more comprehensive oversight approach. Finally, having regular reporting of progress will help ensure DOD leadership and the Congress have the information needed to help make critical funding and policy decisions. In the Fiscal Year 2020 National Defense Authorization Act, Congress mandated that DOD create a comprehensive strategy for improving depot infrastructure by October 2020. DOD issued this strategy in November 2021, but excluded discussion on managing service depot investments. According to OSD officials, annual updates to Congress will include information on service depot investments. However, they don't expect to complete this effort until fiscal year 2024. To fully implement this recommendation, DOD needs to provide evidence of actions taken to manage service depot investments. As of July 2025, DOD has not provided additional information related to this recommendation.

|