Chemical Innovation: Technologies to Make Processes and Products More Sustainable

Fast Facts

Can the chemistry behind medicines, personal care products, and other everyday items be improved? We examined “sustainable chemistry.”

Stakeholders generally didn't agree on how to define or assess sustainable chemistry. However, they cited several common themes, such as using fewer non-renewable resources and considering all stages of a product's life cycle when evaluating environmental impact.

We looked at more sustainable alternatives in 3 categories of chemistry technologies, such as renewable, less toxic solvents; catalysts from abundant metals such as iron; and processing methods that use energy and materials more efficiently.

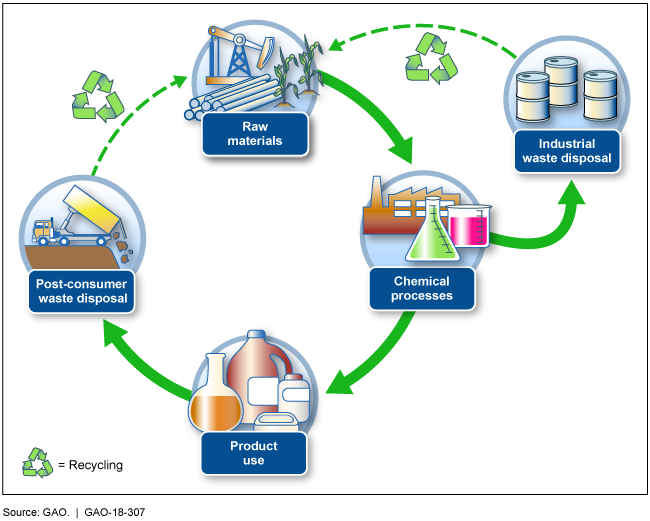

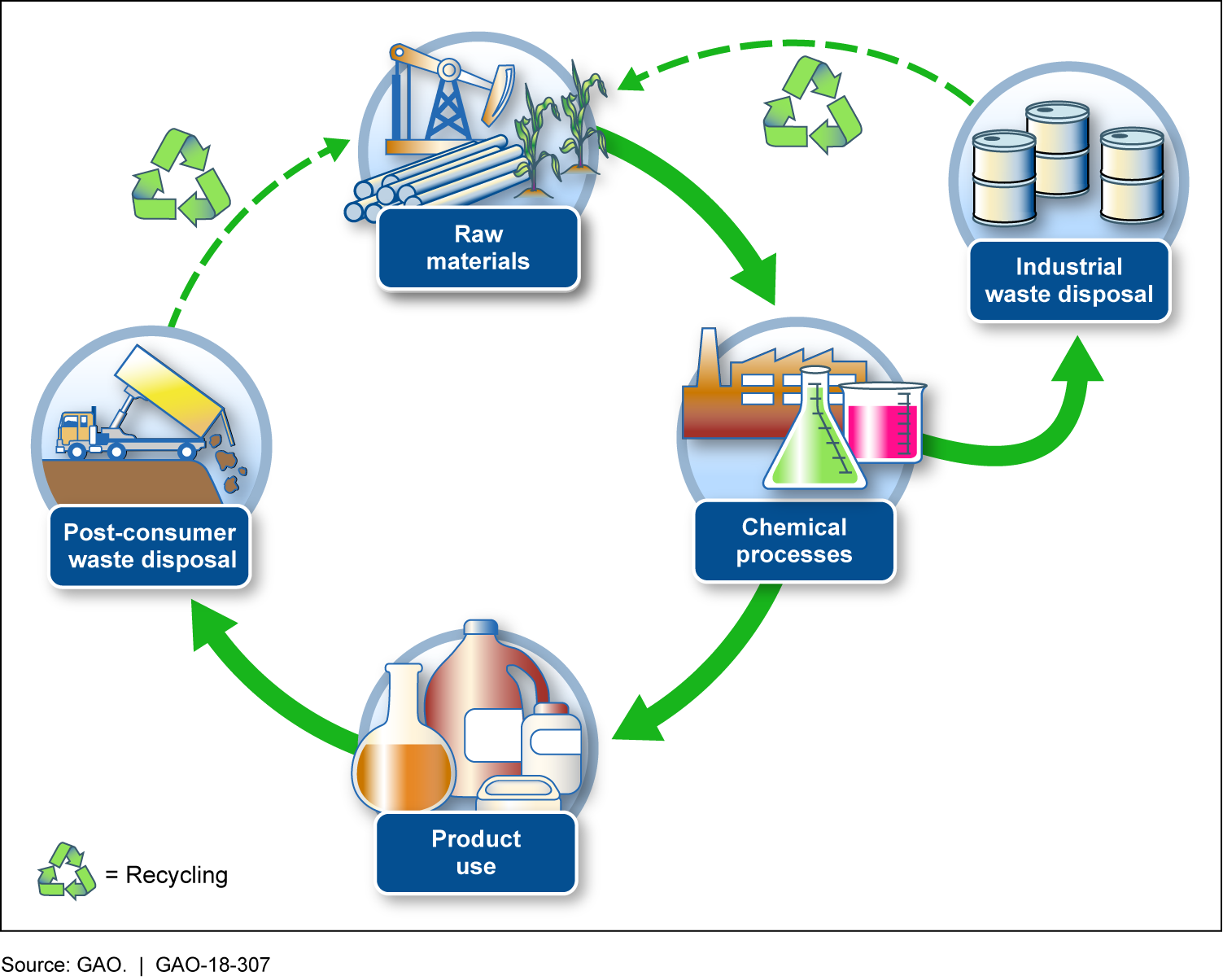

Life cycle of chemical processes and products

This graphic shows various stages of chemical products and chemical processing.

Highlights

What GAO Found

Stakeholders lack agreement on how to define sustainable chemistry and how to measure or assess the sustainability of chemical processes and products; these differences hinder the development and adoption of more sustainable chemistry technologies. However, based on a review of the literature and stakeholder interviews, GAO identified several common themes underlying what sustainable chemistry strives to achieve, including:

- improve the efficiency with which natural resources—including energy, water, and materials—are used to meet human needs for chemical products while avoiding environmental harm;

- reduce or eliminate the use or generation of hazardous substances in the design, manufacture, and use of chemical products;

- protect and benefit the economy, people, and the environment using innovative chemical tranformations;

- consider all life cycle stages including manufacture, use, and disposal (see figure) when evaluating the environmental impact of a product; and

- minimize the use of non-renewable resources.

Life cycle of chemical processes and products

GAO identified three categories of more sustainable chemistry technologies—catalysts, solvents, and continuous processing—that demonstrate both progress and potential.

- Catalysts reduce the energy input required for a chemical process and allow for more efficient use of materials. Stakeholders suggested future research be directed at developing less toxic or renewable catalysts, including those that are metal-free or those from earth-abundant metals such as iron.

- Solvents are used in many chemical processes but can create waste issues and be toxic. Alternatives include solvents from renewable, non-petroleum raw materials and solvents such as water that are less hazardous to human health and the environment, among other qualities.

- An alternative to traditional batch processing is continuous processing, in which materials react as they flow along a system of channels, pipes, or tubes. Compared to batch processing, continuous processing uses materials more efficiently, generates less waste, and has a smaller physical footprint.

The federal government and other stakeholders play several roles, sometimes in collaboration, to advance the development and use of more sustainable chemistry technologies. The federal government has supported research, provided technical assistance, and offered certification programs, while stakeholders have integrated sustainable chemistry principles into educational programs and addressed chemicals of concern in consumer products. While switching to more sustainable options entails challenges, this field has the potential to inspire new products and processes, create jobs, and enhance benefits to human health and the environment. Stakeholders identified strategic implications of sustainable chemistry and offered a range of potential options to address challenges and realize the full potential of these technologies, including the following:

- Breakthrough technologies in sustainable chemistry could transform how the industry thinks about performance, function, and synthesis. Sustainable chemistry creates opportunities to use a different conceptual framework that allows industry to create molecules with better performance.

- The establishment of an organized constituency, with the involvement of both industry and government, could help make sustainable chemistry a priority. An industry consortium, working in partnership with a key supporter at the federal level, could lead to an effective national initiative or strategy.

- A national initiative that considers sustainable chemistry in a systematic manner could be useful. Such an effort could encourage collaborations among industry, academia and the government, similar to other national technology Initiatives.

- There are opportunities for the federal government to address industry-wide challenges. Federal attention that facilitates development of standard tools for assessment and a robust definition could help clarify relevant participants in the field and improve information available for decision-makers at all levels.

According to stakeholders, transitioning toward the use of more sustainable chemistry technologies will require national leadership and industry, government, and other stakeholders to work together.

Why GAO Did This Study

Chemistry contributes to virtually every aspect of modern life and the chemical industry supports more than 25 percent of the gross domestic product of the United States. While these are positive contributions, chemical production can have negative health and environmental consequences. Mitigating these potential consequences requires thoughtful design and evaluation of the life cycle effects of chemical processes and products.

GAO was asked to conduct a technology assessment to explore, among other things, the opportunities, challenges, and federal roles in sustainable chemistry. This report discusses (1) how stakeholders define and assess sustainable chemistry; (2) available or developing technologies to make chemical processes and products more sustainable; and (3) how the federal government, industry and others contribute to the development and use of such technologies.

GAO selected for assessment three technology categories—catalysts, solvents, and continuous processing; interviewed stakeholders from various fields, such as government, industry, and academia; convened a meeting of experts on sustainable chemistry technologies and approaches; and surveyed a non-generalizable sample of chemical companies. GAO is not making recommendations in this report, but is identifying strategic implications.

For more information, contact Timothy M. Persons at (202) 512-6412, personst@gao.gov or John Neumann at (202) 512-3841, neumannj@gao.gov.