Defense Inventory: Further Analysis and Enhanced Metrics Could Improve Service Supply and Depot Operations

Highlights

What GAO Found

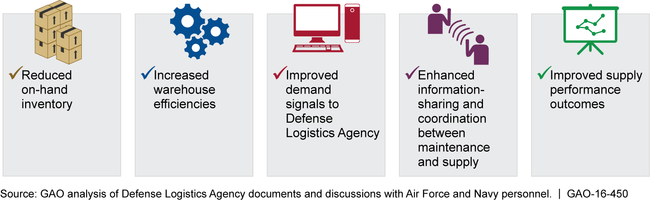

The military services have, to varying degrees, transferred retail supply, storage, and distribution functions at their depot-level industrial sites to the Defense Logistics Agency (DLA) and achieved some efficiencies, but have not fully assessed the costs and benefits of transferring more retail functions to DLA at Army and Marine Corps depots and Navy shipyards. Specifically, Air Force Air Logistics Complexes (ALC) and Navy Fleet Readiness Centers (FRC) transferred all retail supply, storage, and distribution functions to DLA over the course of several years. For example, according to officials and GAO's assessment, these changes have led to a number of benefits, including a 20 percent reduction in on-hand inventory and a 10 percent reduction in backorders at the Air Force ALCs over a 5-year period (see figure for examples of benefits).

Examples of Benefits from the Defense Logistics Agency Handling Retail Supply, Storage, and Distribution Functions at Service Industrial Sites

By contrast, the Army and Marine Corps have retained most supply functions at their depots and DLA manages inventory at the Navy shipyards while still using Navy systems and processes, rather than those of DLA. The Navy and DLA began to transition to DLA business processes and systems at Norfolk Naval Shipyard in 2012, but the Navy reversed course after 7 months when it resulted in increased waits for inventory and work stoppages. Meanwhile, DLA is pursuing limited steps to improve retail supply, storage, and distribution functions at the industrial sites to improve supply support and overcome service concerns. However, the Department of Defense (DOD), DLA, Army, Navy shipyards, and the Marine Corps have not conducted business case analyses on the benefit of additional transfers of retail functions, though the Army is planning to conduct one. Without such analyses, decision makers will not be positioned to ensure that further transfers of retail functions, if warranted, are efficient and effective.

DOD, DLA and the services have some internal efficiency measures, but they generally do not have metrics that would allow for more effective and efficient management of supply and maintenance operations. Specifically, DOD, the services and DLA have not adopted metrics on the accuracy of planning factors, such as the accuracy of part lists, or the costs created by backorders. Officials noted that accurate planning factors improve demand forecasts needed to minimize backorders and excess inventory. Without relevant metrics on cost and planning factors, DOD, DLA and the services will be unable to optimize supply and maintenance operations and may miss opportunities to improve the efficiency and effectiveness of depot maintenance.

Why GAO Did This Study

DOD manages approximately $97 billion of inventory. To enhance efficiency and effectiveness, the 2005 base realignment and closure round and a June 2005 decision by the Under Secretary of Defense for Acquisition, Technology, and Logistics required the military services to transfer to DLA all of their retail inventory supply, storage, and distribution functions at most depot-level industrial sites.

Senate Report 114-49, accompanying a bill for the National Defense Authorization Act for Fiscal Year 2016, included a provision for GAO to examine DLA's supply support to DOD industrial sites.

This report evaluates the extent to which (1) the services have transferred retail supply, storage, and distribution functions at DOD industrial sites to DLA, and whether the results have been used to inform future efforts, and (2) DLA and the services have adopted metrics that allow them to effectively and efficiently manage supply and maintenance operations. GAO reviewed DOD, DLA, and service guidance and documentation; evaluated DLA and service processes; and interviewed officials.

Recommendations

GAO is making six recommendations including that DLA, the Army, Navy shipyards, and Marine Corps conduct business case analyses, drawing on lessons learned, to determine if further transfer of retail functions is warranted, and that DOD, DLA, and the services develop metrics to monitor costs and accuracy of demand planning factors. DOD concurs with GAO's recommendations.

Recommendations for Executive Action

| Agency Affected | Recommendation | Status |

|---|---|---|

| Department of Defense | To increase department-wide supply chain efficiencies and effectiveness in support of maintenance at the Army and Marine Corps depots and Navy shipyards, the Secretary of Defense should direct the Assistant Secretary of Defense for Logistics and Materiel Readiness, in conjunction with the Director, Defense Logistics Agency, and the Secretaries of the Army and Navy and the Commandant of the Marine Corps to assess through a comprehensive business case analysis-drawing on lessons learned from previous efforts-the costs and benefits of DLA managing the retail supply, storage, and distribution functions at the Army and Marine Corps depots and Navy shipyards. |

The Department of Defense (DOD) agreed with GAO's June 2016 recommendation; however, as of February 2025, a comprehensive business case analysis had not been completed for the Navy shipyards. In November 2017, DOD designated the transfer of these retail functions as an operating priority and identified it as a key reform effort within logistics in the department. In June 2018, the Marine Corps had conducted an analysis and decided to transition additional supply, storage, and distribution functions to DLA with full operating capability occurring in October 2023, according to DOD officials. As of March 2019, the Army also had developed a comprehensive business case analysis that examined several different courses of action for transitioning supply, storage, and distribution functions to DLA. Based on the results of this analysis, the Army determined that it should continue utilizing DLA for storage and distribution at select industrial base facilities and not utilize DLA for supply operations. Lastly, the Navy and DLA in August 2018 signed a strategic memorandum of agreement that identifies the roles and responsibilities of different organizations with respect to supply, storage, and distribution in support of Navy shipyards. However, as of February 2025, a comprehensive business case analysis had not been completed. Without the Navy completing a business case analysis, decision makers will not be positioned to make cost-effective decisions regarding supply operations at the Navy shipyards.

|

| Department of Defense | To increase department-wide supply chain efficiencies and effectiveness in support of maintenance at the Army and Marine Corps depots and Navy shipyards, the Secretary of Defense should direct the Assistant Secretary of Defense for Logistics and Materiel Readiness, in conjunction with the Director, Defense Logistics Agency, and the Secretaries of the Army and Navy and the Commandant of the Marine Corps to use the analysis to make a decision on the degree to which DLA should manage these functions at the Army and Marine Corps depots and Navy shipyards. |

The Department of Defense (DOD) agreed with GAO's June 2016 recommendation. While the Army and Marine Corps have conducted a comprehensive business case analysis and made decisions on how best to incorporate DLA into depot operations, the Navy has not completed a comprehensive business case analysis, preventing an informed decision on the transfer of supply, storage, and distribution functions to DLA, as of February 2025. In February 2023, the Army decided based on its evaluation to continue using DLA for storage and distribution at select industrial base facilities and not utilize DLA for supply operations. The Marine Corps conducted an analysis and decided to transition additional supply, storage, and distribution functions to DLA in October 2023. In February 2023, the Under Secretary of Defense for Acquisition and Sustainment directed the Navy to provide an update on their implementation progress to fully consolidate the Navy SS&D mission under DLA. As of February 2025, the Navy has not provided an update to OSD or GAO. Without the Navy making decisions based on comprehensive business case analyses on the degree to which additional supply, storage, and distribution functions will transfer to DLA, DOD will not be assured that it is operating its supply operations at the Navy shipyards in a cost-effective manner.

|

| Department of Defense | To improve the efficiency and effectiveness of supply and maintenance operations, in accordance with DOD guidance, the Secretary of Defense should direct the Assistant Secretary of Defense for Logistics and Materiel Readiness, in conjunction with the Director, Defense Logistics Agency, and the Secretaries of the Army, Navy, and Air Force and the Commandant of the Marine Corps to develop and implement metrics that measure the accuracy of planning factors, such as the schedule, bill of materials, and replacement factors, used for depot maintenance. |

DOD concurred with our recommendation and took actions that met the intent of our recommendation. As of January 2020, DOD had conducted a depot maintenance work packages and bill of materials study. This study examined available data from the military services and determined that the accuracy of maintenance work packages and bills of materials were not a systemic factor in depot maintenance delays. The study determined that planned overhaul depot maintenance flow days and material costs were the most appropriate metrics for measuring the accuracy of planning factors. These metrics are already tracked and monitored by the military services. Thus, DOD did not develop and implement any new metrics to measure the accuracy of planning factors.

|

| Department of Defense | To improve the efficiency and effectiveness of supply and maintenance operations, in accordance with DOD guidance, the Secretary of Defense should direct the Assistant Secretary of Defense for Logistics and Materiel Readiness, in conjunction with the Director, Defense Logistics Agency, and the Secretaries of the Army, Navy, and Air Force and the Commandant of the Marine Corps to take action, as appropriate and necessary, to resolve any issues identified through measuring the accuracy of planning inputs in an effort to improve supply and depot maintenance operations. |

DOD concurred with our recommendation and took actions that met the intent of our recommendation. As of January 2020, the maintenance work packages and bill of materials study-previously discussed in recommendation three-disproved the hypothesis that improving the accuracy of repair bills of material will decrease depot overhaul flow days and reduce materiel costs. During the analysis, several individual items for some of the evaluated weapon systems were identified as having led to an increase in depot maintenance flow days and materiel costs. When the weapon system was undergoing maintenance overhaul, unexpected technical problems were found with the items requiring them to be replaced. For these select items, the industrial base needed time to respond to new a demand that had not previously been experienced. In these cases, stockage policy (i.e., the amount of inventory held by DOD) for the individual item was not causing the problem. As a result of the analysis conducted, DOD was able to determine that an enterprise solution would not be appropriate.

|

| Department of Defense | To be able to assess the cost-effectiveness of supply and depot maintenance operations, in accordance with DOD supply chain management guidance, the Secretary of Defense should direct the Assistant Secretary of Defense for Logistics and Materiel Readiness, in conjunction with the Director, Defense Logistics Agency, the Secretaries of the Army, Navy, and the Air Force, and the Commandant of the Marine Corps to take steps to develop and implement metrics, to the extent feasible, to measure and track disruption costs created by the lack of parts at depot maintenance industrial sites by, for example, establishing a team of supply and depot maintenance experts from DLA and the services to assess potential data sources, approaches, and methods. |

DOD concurred with our recommendation and took actions that met the intent of our recommendation. As of January 2020, DOD had conducted a study of available Air Force and Navy aviation depot activity data on whether a lack of spare parts are a significant impact on costs in the depot environment (i.e., a disruption cost) and the availability of aircraft. As a result of the study, the department was able to determine that there was no systemic causal relationship between the lack of spare parts in the depot environment and the cost of depot maintenance and the availability of aircraft.

|

| Department of Defense | To be able to assess the cost-effectiveness of supply and depot maintenance operations, in accordance with DOD supply chain management guidance, the Secretary of Defense should direct the Assistant Secretary of Defense for Logistics and Materiel Readiness, in conjunction with the Director, Defense Logistics Agency, the Secretaries of the Army, Navy, and the Air Force, and the Commandant of the Marine Corps to take action, as appropriate, to address any inefficiencies identified by the disruption cost metrics in supply and depot maintenance operations. |

DOD concurred with our recommendation and took actions that met the intent of our recommendation. As of January 2020, DOD had determined after a study of Air Force and Naval Aviation depot activity data, that there was no causal relationship between a lack of parts in the depot environment and depot maintenance costs (i.e., disruption costs) and the availability of aircraft. As a result, the department could not identify actions to address disruption costs (given that the study determined that disruption costs due to a lack of spare parts was extremely minimal).

|